What is a Spring Loaded Contact Test Probe?

Spring-loaded contact test probes are also referred to as Pogopins, Contact pins, fixture pins, spring pins, test pins, and bed of nails.

To make contact with various test points on Printed Circuit Boards (PCBs), components, and wiring fields, spring contact test probes are used. The probes may test connector-cable systems when they are used in specialized test modules. The test probes can also be used as a charging contact or in control engineering units.

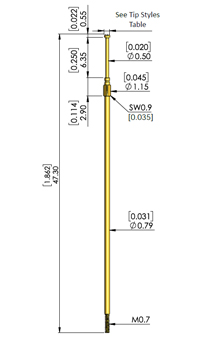

A tubular barrel, a spring, and a plunger are the components of a spring-loaded contact test probe. Different tip styles and spring tensions are available for plunger tip styles. The test surface is best-contact guaranteed.

Additionally, probes can be fixed inside housing units (receptacles) where an electrical connection is made. Also, makes it simple to remove the test probes for repair or replacement.

There are several applications for contact probes. Here’s a summary:

● ICT/FCT series - Probes for fixtures. Standard ATE probes for different centers

● Short Travel Probes/Battery contact series - Limited travel compact probes. Frequently used as a battery contact

● Interface Probes - Interface between the fixture and test system are usually realized by this option

● Pneumatic Probes - For the limited access, selective contacting of a single test point

● Threaded Probes (screw-in) - Threaded to provide a secure fit. Used to test wire harnessing in modules.

● High Current Probes - Used for applications requiring a high current.

● Switch Probes - Special probes with integrated switch elements are mainly used for presence tests.

● Push Back Probes - During the push back of connectors, the tight seat of the connector elements is verified.

Because of their numerous benefits, spring-loaded contacts have grown to be a favorite among engineers. And they could be benefiting you.

Advantages of Spring-Loaded Contact

- Solderless inter-connections

- Easy integration into systems

- Designed for durability

- Misalignment accommodation

- Consistent contacts

- High Vibration Tolerance

- Easy mating with other components

- Perfect for blind mating

- Self-cleaning components

- Excellent contact for cable termination

- Diversity of designs

Just Leave it to us, we have it covered!

Every design has unique specifications, and we are able to create the spring-loaded contacts you need to bring your idea to life.

We specialize in precision machined components, thus we are the experts in the industry when it comes to spring-loaded connections. We give you the products you want for your unique design needs.

Get your every component as per your need at https://equip-test.com/

| https://equip-test-probes.blogspot.com/2022/08/equip-test-radio-frequency-testing.html |

| https://equip-test-probes.blogspot.com/2021/11/agilent-3070-in-circuit-test-ict-system.html |