The spring contact probes are used to create

an electrical connection between the object that to be tested and the testing

system. These contact probes are primarily used for electrical testing of

printed circuit boards, connectors, cables and various other electrical

components and assemblies. The main advantages of the spring contact probes are:

·

Constant contact resistance.

Constant contact resistance.

·

High pointing accuracy.

·

Longevity.

·

High currents and frequencies as

possible.

·

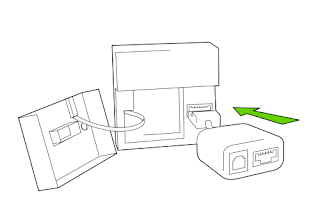

Easy installation in the test

adapter by using receptacles

·

Interchangeable.

Other categories are interface probes, probes with

rolling ball, switch probes, high current probes, threaded probes; pneumatic

probes etc. Flat tip pin size contact probe is suitable for solder pads and

contact pins. Different uses of contact probes are according to the tip pin

size. High current probes are used for high current application, specially

designed for a very small probe resistance.

Probes are a durable component, which can

perform several hundred thousand contact cycles with stable contact resistance.

The variety of spring contact probe allows the user to find the perfect test

needle for each application. Each probe

is used for different purposes. The users have to choose according to the tip

style, length, spring force and travel time. Moreover, the

spring contact probes are used to

test the printed circuit boards, connectors, wire harness and other electronic

components. They can be used in interfaces and easily removable electrical

connections. The contact probes of springs do not require tolerance

compensation because they are suitable for all contacting requirements in

two-terminal measurement. Altogether, the contact probes of spring produce

different materials such as brass, steel or copper beryllium. It contains a broad

range of head shapes with a diameter between 0.5 and 3mm forms of your standard

product range. You can find the spring contact probes from Equip-test.